19 December 2019

For our ARCELORMITTAL customer, AVIME produced the plans and manufactured a coke gas extractor rotor.

The various stages of the manufacture were:

- Three-dimensional readings on the existing rotor

- Compilation of the manufacturing and machining plans

- Cutting in 2 parts of the wheel from one forged piece

- Electron beam welding (without addition of material)

- Machining of a forged 42CrMo4 steel shaft

- Frettage par chauffe de la roue et refroidissement de l’arbre à l’azote liquide, le serrage obtenu est de plusieurs 1/10è de mm, sans clavetage

- Dynamic balancing on the bench class G0.5 as per the NF E 90 600 standard

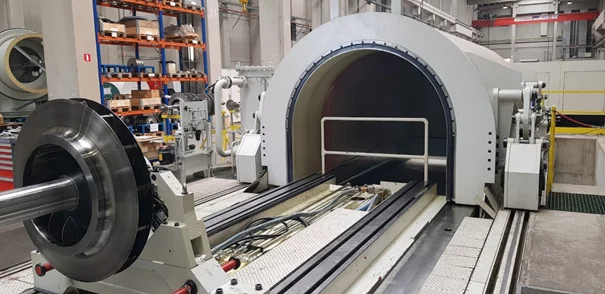

- Overspeed test in vacuum chamber, at design rotation speed + 20% = 7,350 rpm

- Balance check after overspeed

- Application as per DIN 28 053 standard for a ceramic + PTFE based anti-corrosion and anti-adherent coating

- Balance check after coating