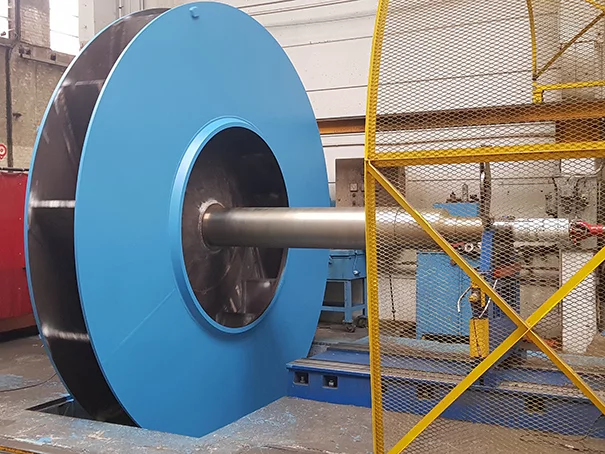

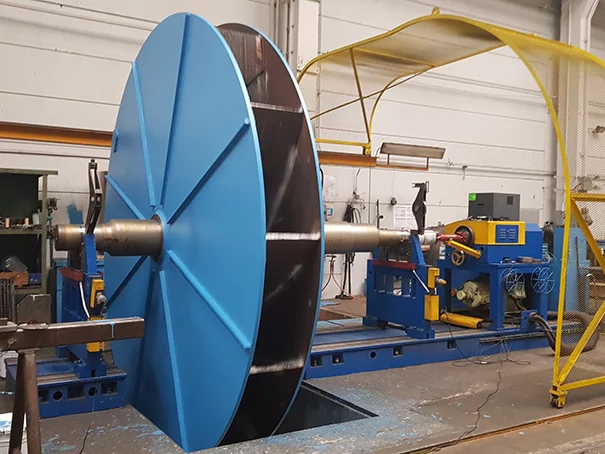

At the beginning of 2020 AVIME delivered an exceptionally large rotor wheel. The design work and the manufacture were all completed within a very short period of 6 months.

The unforgiving industrial process of which this fan is a part, is one with very high temperatures and levels of abrasive dusts. The rotor was therefore manufactured from the most suitable materials as identified by our engineering design team. It is also protected against abrasion and is equipped with wearing plates. The assembling and manufacture were carried out applying a very strict procedure, subject to regular non-destructive testing such as radiography, ultrasound and penetrant inspection for the main welding points.

On-site, the fan is constantly monitoring using on-line temperature probe and vibration sensor instrumentation fitted to the bearings by the end customer.

Principal characteristics:

- Dimensions: ø4m – wt. 12t

- Flow rate: 450,000 m3/hr

- Motor power: 2,500 kW

- Rotation speed: 900 rpm

- Temperature: 300°C with peaks of 450°C

- Balancing Standard and Class: NF E 90 600 – G2.5

Images of the product during construction